You may have encountered the term “bunker” in a general discussion; however, the relation and context is usually military installations or personal safety during extreme conditions. Bunkering, for the maritime context, is a term describing a process of supplying fuel to ships for own usage; found in ports. Another relevant term/acronym is BAF or Bunker Adjustment Factor; referring to floating parts of sea freight charges which represent additions due to fuel prices.

Fuel, obviously is an important regular of the ship as well as the shipping industry as a whole; its high cost warrants storage and careful use; keeping track of use and supply. The practice itself also involves specifications of the oil to be taken onboard; lube oil, heavy oil, low-sulphur heavy oil and diesel oil. Occasionally, oil comes in drums therefore NOT considered as bunkering while oil pumped on-ship does. Regarding oil itself, viscosity plays an important role since changes were administered to 99 CST instead of normal 380 alongside having a temperature of 15 Celsius with sulphur content being less than 3.5%. (marinegalaxy.com, 2014)

However, some hitches may take place since older vessels have issues with HFO (Heavy-Fuel Oil) meters in terms of errors in readings; warranting regular maintenance. Another hitch involves tanks of ships not being cleaned regularly; sometimes carrying remnant of 15-18 tonnes with chance of leaks in heating coils. The category/task of ships along with weather conditions sometimes is also an issue with bunkering in a way that quantity of diesel fuel is considerably less aboard vessels while sailing through colder regions; causing condensation of the tank. Condensation effects can be minimised by frequent DO checks for presence of water in tanks.

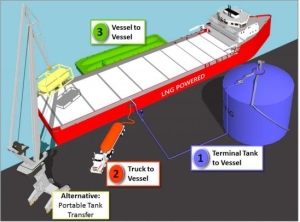

Leading onto more modern schemes of most ships converted to LNG therefore requiring a different bunkering methods to conventional fuel; depending on the sourcing of the fuel itself. (See below)

(Image courtesy of ABS)

As seen above, LNG bunkering leverages multi-modal transports from all dimensions. However, according to ABS, (2014) some operators are considering using disposable, portable tanks that are preloaded with the fuel and installed at any facility capable of transferring containers to vessels.

However, LNG bunkering carries more risks to personnel than conventional fuel due to it being still a new concept and still remains to be fully controlled. Firstly, LNG is primarily methane, a non-toxic flammable gas where the fuel itself is created by liquification; cooling of the gas below its boiling point. (-260F) LNG is a cryogenic liquid that can pose its hazards due to uncontrolled release.

Some examples are skin injuries to personnel (similar to thermal burns) as well as damages to more sensitive tissue such as eyes; prolonged contact leads to frostbite alongside asphyxiation if inhaled. Damage to surrounding structures also occurs due to the cryogenic temperatures; causing materials such steel to become brittle and therefore shatter. More serious damage, however can occur with the formation of a flammable cloud which is capable of serious thermal damage to surroundings.

Finally, as opposed to regular oil, the LNG fuel has unique traits such as volatility and cryogenic conditions; storage of which maximises potential damage with the large amount in one place. Risks in the bunkering procedures start from initiating events which involve machinery as well as the maintenance itself. Leaks in pumps, pipes and other connectors are caused by corrosion and wear of machine parts; along with vibration, seal failure, incompatible hoses, valves and improper installation. Connections are also an issue within hoses and their valves where frequent movement during operation and inadequate mooring and extreme weather conditions. Lastly, operators themselves are an issue with LNG storage since some errors are related to human factors and operation errors. One such error is the overfilling, overflowing, overpressurising of storage tanks. This error can be averted by simple increase in attention from the side of the operator and tech staff.